Air Filter Highlight: P312

The Purolator P312 is an industrial-strength disposable panel air filter that utilizes a durable synthetic polyester fiber media. It is designed for residential, commercial, and light industrial applications where a high-performing synthetic filter is needed. The P312 can serve as a replacement for traditional fiberglass F-312 filters.

The polyester fiber media has a MERV 4 rating and provides average arrestance ratings of 82% for the 1" model and 89% for the 2" model in capturing airborne particulates.

The filter's frame is constructed from post-consumer recycled materials in a unique "Monobond pinch" design. This one-piece frame is heat and pressure-sealed to the media around the entire perimeter.

This continuous bonding eliminates potential air bypass points at the corners for improved sealing. The high tensile strength binder used provides enhanced frame integrity to withstand temperature and humidity fluctuations.

The polyester fiber media itself is manufactured with an interlocking pattern of small fiber strands that create tiny shaped dust traps. This design maximizes the filter's dust loading capability while minimizing resistance to airflow to reduce energy costs.

The synthetic media makes the P312 particularly well-suited for environments with large amounts of lint, dust and other particulates.

The P312 is classified as a UL Class 2 Air Filter per UL 900 standards for flammability.

Pinch frame design

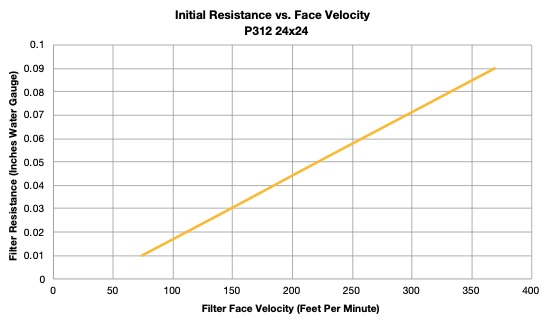

The P312 air filter is available in two depth options - 1" and 2". These differ in their initial resistance and final recommended change-out resistance based on the air flow velocity across the filter face.

Filter resistance, measured in inches of water gauge (w.g.), represents the pressure drop across the filter media as air passes through. A higher resistance means the fan must work harder to move air, increasing energy costs. The initial resistance specifies the clean filter pressure drop, while the change-out resistance is the maximum recommended level before replacement.

For the P312 at a typical face velocity of 300 feet per minute (fpm):

• 1" depth: Initial resistance of 0.16" w.g., change-out at 0.5" w.g.

• 2" depth: Initial resistance of 0.19" w.g., change-out at 1.0" w.g.

The deeper 2" filter has a somewhat higher initial resistance compared to the 1" model due to the air passing through more filter media. However, it can handle a much higher final resistance before change-out (1.0" w.g. vs 0.5" w.g.) because the larger surface area can trap more particles before becoming overly loaded.

Face velocity directly impacts filter resistance - higher air flow rates result in higher initial and final resistances. While 300 fpm is common for commercial HVAC systems, residential systems may be in the 200-400 fpm range.

The ability to run at higher final resistance allows the 2" filter to last longer between replacements. But the trade-off is higher fan energy use over its lifetime due to the increased static pressure. Ultimately, filter selection depends on balancing system air flow requirements, desired filter life, and operating costs.

Key benefits of the P312's pinch frame design include improved aerodynamics to reduce airflow resistance, safe and easy installation, increased effective filtering area compared to similar sizes, and availability in a wide range of standard dimensions.

Overall, the P312 provides an industrial-grade synthetic filter option for cost-effectively capturing high levels of airborne particulates across HVAC systems in diverse applications.

Its durable construction, enhanced dust loading capability, and improved energy efficiency make it a leader in the high-velocity pre-filter market.

You may also like:

• 5 Benefits of Purolator Air Filters

• How Often Should I Change My Air Filters?

• 4 Ways to Make Your Air Filters Last