Purolator Air Filters FAQ

What is your shipping policy?

We offer flat-rate shipping for $15 on all orders.

Please note that while we strive for timely delivery, shipping times are estimates and may vary. We'll provide you with an estimated delivery date when you place your order, but actual delivery times might differ slightly depending on various factors.

For more detailed information about our shipping process, please contact our customer service team.

What is your return policy?

We accept returns of resalable items within 60 days of purchase. To return an item:

• Contact our Customer Care Team for a Return Merchandise Authorization (RMA).

• Ship the item back within 30 days of receiving the RMA.

• Return the product in its original packaging, unopened and undamaged.

Please note:

• A 25% restocking fee may apply.

• Custom or non-stock items are generally not returnable.

• Returned items must be in full cartons.

• For full details and exceptions, please see our complete Return Policy.

Filter Basics

Your home filter is also called a "furnace filter". The purpose of your furnace filter is to keep the coils and heat exchanges on the heating and air conditioning system clean. You will want to keep the filter clean to extend the life of your HVAC unit.

The most important thing to remember about home air filters is to change them regularly. To be safe and keep the air in your home clean we recommend changing 1" filters every month, 2" filters every 1-2 months, and 4-5" filters every 3-6 Months.

Fiberglass air filters most commonly called "throwaway filters", these are the fiberglass weave or "hog hair" filters that are designed to meet the minimum requirements of protecting your air handler (furnace or Air Conditioner) and its components. NAFA (National Air Filtration Association) no longer recommends using anything under a MERV 7 filter for home HVAC systems.

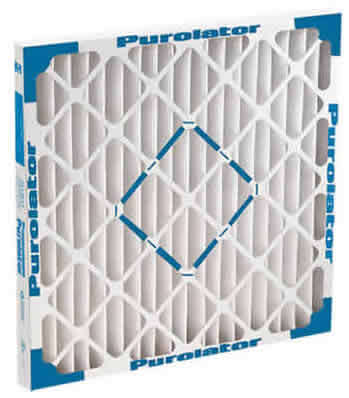

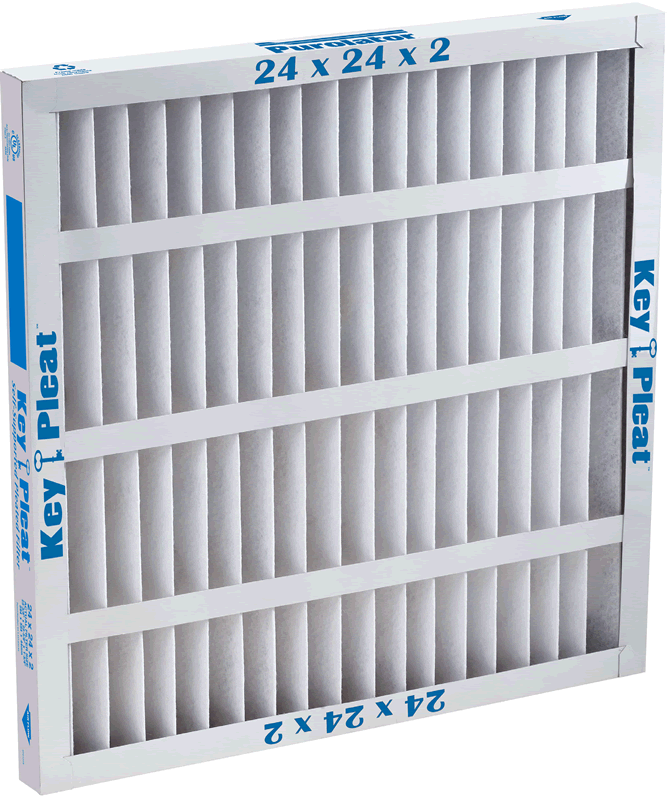

A pleated furnace filter is for those wanting to step up from a basic furnace filter. Pleated filters offer better protection against dust and other airborne particulate.

How do I figure out what size air filter I need?

1. Check your current filter: The easiest method is to look at the old filter in your return air vent. The size should be printed on the filter's frame.

2. Measure the return vent: If there's no filter present, measure the length and width of the return air vent opening as accurately as possible.

3. Multiple sizes: Keep in mind that homes often have 2-3 different filter sizes. Check each return air vent to ensure you order all the sizes you need.

4. Measure precisely: Accurate measurements are crucial to ensure proper filtration and prevent air leakage.

If you're unsure or have an unusual size, contact our customer service team for assistance.

When should I change my furnace/ residential air filter?

For most residential HVAC systems, you should change your air filter every 60-90 days. However, this can vary based on several different factors:

Filter type: Different filter types provide different lifespans. For example, fiberglass filters might need more frequent changes than pleated filters.

Home environment: Pets, smoking, or high dust levels may require more frequent filter changes.

HVAC usage: Running your HVAC system more often can result in needing to change filters more frequently.

Allergies or respiratory issues: Individuals with these concerns may benefit from more frequent air filter changes.

Filter efficiency: Higher MERV-rated filters might need to be changed more often as they trap more particles.

Visible dirt: If you can see dirt accumulation on the filter, it's time for a filter replacement.

As a general rule, check your filter monthly and replace it when it appears dirty, regardless of the time elapsed. This ensures optimal HVAC performance and maintains good air quality in your home. For more detailed information about filter types and their impact on your HVAC system, consult our team of specialists or refer to your system's manual.

What factors affect air filter performance in residential HVAC systems?

All filters, whether they're commercial or residential, battle the same three forces of nature

- Resistance to flow

- Amount of dust they will hold

- Efficiency or ability to remove particles from the air

Residential heating and air conditioning equipment present several challenges for the homeowner from the standpoint of air filtration.

The first limiting factor involves filter depth. Most older homes have an air handler with a 1-inch slot for an air filter inside the unit. This filter is changed by removing the door to the unit and removing and reinstalling the filter.

Newer homes have a filter grille, located at the return air opening. This grille is hinged and can be opened to expose a track for a 1-inch filter. In short, regardless of where the filter is located in a residential unit, there is usually only 1-inch in depth allocated for the air filter.

The second limiting factor is the blower horsepower of residential units. The standard unit has a 1/4 or 1/3 horsepower blower that allows for a *limited amount of resistance to the flow of air.

Anything in the system is considered resistance, but the typical things in a residential system are ductwork (a friction factor to the flow of air), air conditioning coils, grilles, and registers, sometimes fire dampers and filter(s).

Resistance in an HVAC system is measured in inches of water - pressure forcing water to rise in an enclosed tube. Residential units can normally have about 0.5 inches of added pressure in the system and the typical unit is allocated only about 0.1 inches (w.g.) for filters.

And, media filters increase in the resistance to flow as they load with dust. This increase in resistance leads to a decrease in velocity of airflow in your unit.

Because of the 1-inch restriction combined with a limited allocation for pressure, homeowners are limited as to their choices of filters for their home without retrofitting the system.

The choices in the 1-inch variety are normally:

- Standard Fiberglass Throwaway Filter - these filters are designed to remove only the larger particles from the air and, in industry-designed testing, do not do very well. These filters do have a very low resistance to the flow of air and, for this reason, they're most often sold for home units.

- Pleated Filters - these filters achieve more filter surface area by folding the media into a 1-inch frame and can use a higher efficiency media without adversely affecting the resistance to flow.

- Others - anything that does not fall into the above two categories (metals, plastics, cellulose, electronics, etc.).

In today's marketplace, higher efficiency filters are available at most retail home stores and homeowners need to be aware that some of these filters (usually in the MERV 11 and higher category) may create low airflow problems in their system.

Note: The higher the MERV number, the higher the efficiency.

What is the Merv Rating System?

MERV or Minimum Efficiency Reporting Value, or MERV for short, is a filter rating system devised by the American Society of Heating, Refrigeration and Air conditioning Engineers (ASHRAE) to standardize and simplify filter efficiency ratings for the public.

The higher the MERV rating, the higher the efficiency of the air filter. Simply stated, a MERV 12 filter will remove smaller particles from the air than a MERV 8 filter.

For the consumer, this means that you now have the ability to effectively compare one brand to another. Without any value-added additions, any MERV 8 filter will perform about the same as any other MERV 8 filter. The MERV rating only applies to efficiency.

Merv 1-4 Rated filters will collect most particles of 10 microns or larger. Typical applications of these filters are minimum residential filtration, Light commercials, and minimum equipment production.

Merv 5-8 rated filters are used to trap particles in the 3-10 micron range. Some uses are in industrial and commercial building, high-end residential units, and paint booth/spray and finishing areas.

Merv 9-12 rated filters are used specifically for particles in the 1-3 micron range. High-end residences, upgraded industrial workplaces, and commercial boiling frequently use these.

Merv 13-16 rated Filters remove particles in the 0.3-1 micron range and are used in hospitals, healthcare, and high-end commercial buildings. They are also useful in telecommunication manufacturing facilities.

If allergies or asthma are your concern, we suggest you choose a minimum of a MERV 8 filter.

What's the difference between MERV 8, MERV 11, and MERV 13 filters?

MERV ratings indicate an air filter's ability to capture particles. Here's how MERV 8, 11, and 13 filters compare:

MERV 8 Filters:

• Suitable for most residential uses

• Capture 70-85% of air particles sized 3-10 microns

• Filter out dust mites, mold spores, and pollen

• Good balance of filtration and airflow for older HVAC systems

MERV 11 Filters:

• Provide better filtration than MERV 8

• Capture 85-95% of air particles sized 3-10 microns

• Filter out pet dander and auto emissions in addition to MERV 8 capabilities

• Beneficial for households with people who have allergies or asthma

MERV 13 Filters:

• Highest filtration of the three

• Capture >90% of air particles sized 3-10 microns and 75-90% of particles 1-3 microns

• Can filter bacteria and smoke particles

• Best for homes in areas with poor air quality or for those with severe allergies

The higher MERV ratings mean better filtration but may increase resistance to airflow. Ensure your HVAC system can handle MERV 13 filters before using them, as they could strain some systems if not properly configured.

For most households, MERV 8 filters work well. Consider MERV 11 or 13 if you need enhanced air quality, but always check your system's compatibility first.

Can I use furnace filters as air cleaners for my whole house?

There have been significant improvements on 1" furnace type filters over the last ten years.

The fiberglass furnace filter was originally designed to keep the house ventilation system clean from large particles and debris. Since most of the house furnace blowers are not designed to operate in high static pressure environment, the fiberglass furnace filter can share only a limited amount of pressure drop.

The 1" fiberglass furnace filter with low-pressure drop and low cost naturally became the most common choice.

Two things have changed. The first is a better filter design by adopting a pleated structure to reduce media velocity. Lower media velocity typically leads to higher filter efficiency and lower pressure drop.

Secondly, the variety of specialty media (e.g., tribo-charged media, split fibers, large effective fiber diameter (EFD) melt-blown electret, etc.), has significantly higher initial efficiency with relatively low-pressure drops.

The enhanced performance of some pleated type furnace filters has elevated the traditional role of 1" fiberglass furnace filters from protecting the residential ventilation system to improving the indoor air quality (IAQ) in a residential environment. Pleated type furnace filters, when selected and used properly, can potentially reduce the indoor air pollutants significantly and the advantages are multifold.

For example, for allergy sufferers, houses installed with specialty pleated type media furnace filters can potentially alleviate the symptoms of sneezing, watering eyes, itching throat, postnasal drip, coughing etc. during the pollen season.

The reduction of indoor air particle concentration by pleated type furnace filters can also slow down the settling of dust and respirable particles inside the house.

Why is air filtration important?

Air filtration supplies the means to obtain the level of particulate cleanliness required by any definition of "air conditioning." It extends from the simple task of preventing lint and other debris from plugging heating/cooling coils to removing particles as small as 0.1 microns which could cause a short circuit on a microchip.

In addition to the reasons given above, air filters are used for a wide variety of purposes, some of which include:

- Protecting the general well-being of the occupants of a space

- Protecting the decor of occupied spaces by removing the staining portion of airborne dust

- Reducing maintenance of building interiors by reducing the frequency of washing such items as Venetian blinds and fluorescent bulbs

- Protecting the contents of occupied spaces including paintings, tapestries, and other items of historic or cultural value

- Elimination of fire hazards by removing lint and other materials which might accumulate in ductwork

- Extension of shelf life of perishable dairy products by removing airborne mold during processing operations

- Removing airborne bacteria from operating room air to help prevent postoperative infection